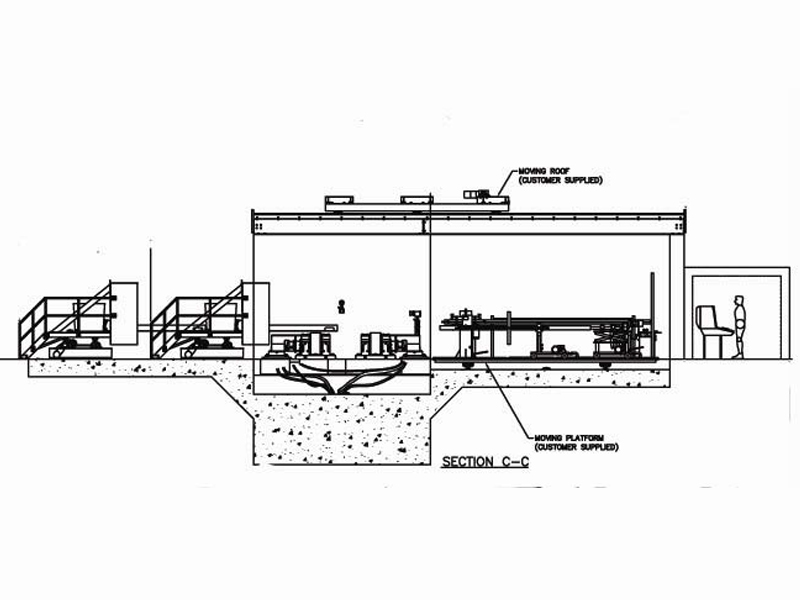

Style: Horizontal

Description:

The Model HS machine is used to cast the outer shell of bi-metal steel rolls as well as heavy tube castings. The machine utilizes a spinning mold, or chill, on four trunnion wheels. Model HS machines are used by some of the premier Bi-Metallic roll producers in the world. Technology transfer is available for HSS and Semi HHS roll applications among others technologies.

STANDARD FEATURES

- Hydrostatic Drive System

- Four Pillow Block Assemblies

- Machine Base Assembly Drawings

- Vibration Monitoring System

- Mold Coating Assembly

- Main Operator’s Console

- Mold Temperature Monitoring

- Industrial Computer

- Pouring System Assembly

- Moving Platform Assembly

- Flux Application Assembly

- Temperature Probe Assembly

- Overhead Moving Roof Assembly

- Mold Cleaning Assembly

- rawings for Auxiliary Items

MODEL HS STANDARDS

- Acceleration: <7 Minutes

- Deceleration: < 5 minutes

- Vibration: <1 mm without a chill, <4-5 mm with chill

- Temperature: < 20 degrees c below the real temperature

TECHNOLOGY AND SERVICE (supplied as required)

- Centrifugal Casting Technical Manuals

- Start Up Service by World Experts in Roll Production.

- Operational parameters for customer application

- 12 month equipment warranty

CASTING ALLOYS

Materials cast include: Carbon Steel, Alloy Steel, Stainless Steel, Gray Iron, Ductile Iron, High Chrome Iron, Roll Materials (ICDP, HCRI, HCRS, HSS, S-HSS) Copper and Copper Alloys, Nickel Alloys and Cobalt Alloys.Models and Specifications:

| Model NO. | WT. LIMIT(LBS) | Casting Size OD MIN. | Casting Size OD MAX. | Casting Length MIN | Casting Length MAX |

|---|---|---|---|---|---|

| HS | 95000 | Custom Sized | Custom Sized | Custom Sized | Custom Sized |